Concrete Guard Lithium

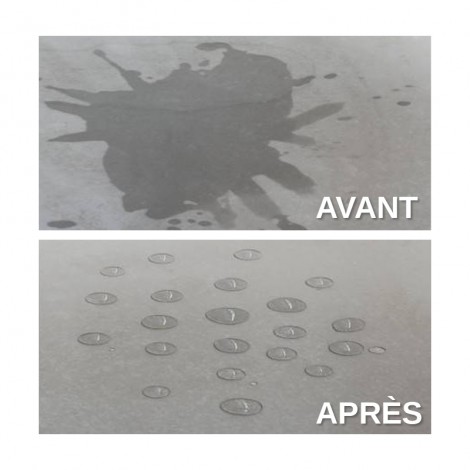

Concrete Guard Lithium is a colorless lithium silicate protection. This finish is hard, stain-resistant, water-repellent, and provides high protection for industrial floors with good chemical resistance and enhanced surface abrasion resistance.

Concrete Guard Lithium is ideal for surfaces requiring increased protection against stains and chemicals.

Packaging: 5L

Coverage: 35-70m²/L per coat

-

Fast delivery (24/48 hours) and free delivery for orders over €350 (mainland France) to your home or to a relay point.

Fast delivery (24/48 hours) and free delivery for orders over €350 (mainland France) to your home or to a relay point.

-

Permanent discounts on public rates for professionals

Permanent discounts on public rates for professionals

-

Do you have a question? An information ? An advice ? Contact our experts at +33 4 92 38 95 67

Do you have a question? An information ? An advice ? Contact our experts at +33 4 92 38 95 67

Concrete Guard Lithium is a transparent, dust-proof finishing treatment for concrete and cement surfaces, polished or unpolished, new or existing, suitable for both indoor and outdoor use. It reduces the absorption of oily substances and aqueous solutions. It can also be used as a stain-resistant finish for stone surfaces and stone-based materials. Recommended applications include: architectural concrete floors, retail shops, showrooms, production, packaging and storage areas, garages and parking lots, cement coatings, exposed precast panels or concrete blocks, limestone and natural stones in general, exposed brickwork, and concrete products.

Key features

- Creates an aesthetically pleasing surface with a high level of gloss.

- Protects the surface, making it dust-proof and abrasion-resistant.

- Forms a microfilm that does not compromise the surface’s breathability.

- Reduces the absorption of water as well as vegetable and mineral oils, without hindering water vapor transmission.

- Increases resistance to chemical attacks, salts, and waterborne pollutants, and helps prevent stains by reducing the adhesion of dirt.

- Enhances the appearance of the treated surface, giving it a glossy finish and increasing mechanical strength.

- Reduces the risk of Alkali-Silica Reaction (ASR).

- Limits the formation of mineral efflorescence, especially on damp substrates.

- Fast drying and easy to apply using a sprayer or microfiber polisher.

- Very low VOC emissions.

- Does not contribute to the formation of expansive gels in alkali-aggregate reactions (unlike sodium and/or potassium silicates).

Instructions for use

1. Surface preparation: apply the product to a dust-free, cohesive, and dry surface using a low-pressure or manual sprayer, spreading it evenly with a damp microfiber cloth or polisher.

2. First coat: the coverage of the first coat will depend on the substrate’s absorption capacity (grain size from sanding and/or presence of densifying hardeners).

3. Second coat: depending on the absorption capacity of the substrate and environmental conditions, apply a second coat as soon as the surface is walkable, usually within one hour. High-speed polishing between coats is not mandatory but recommended to achieve maximum gloss. The second coat will be more effective than the first.

4. Polishing: polish the treated floor at least 2 hours after application using a high-speed polishing machine equipped with a natural fiber pad.

5. Maintenance: after dusting, clean using only clean water when possible. If detergents are used, opt for pH-neutral ones. The use of Stone Sealer & Soap is highly recommended. Avoid acidic products, butyl compounds, and high-boiling solvents such as D-Limonene derived from citrus.

Coverage: between 35 and 70 m² per coat per liter (depending on surface roughness).

Packaging: 5L

Data sheet

- Usage

- Water Repellent Treatment

- Material

- Concrete

Natural Stone

Terrazzo - Environment

- Indoor

Outdoor - Base Type

- Water-based

- Quantity

- 5 L